Garage pads in Edmonton must be engineered to handle extreme temperature swings, frost, depth, and soil conditions unique to Alberta. In a city where extreme temperature swings, frost depth, and soil conditions can make or break concrete work, choosing the right garage pad design and installation method is essential. Many homeowners only realize this after cracks appear, doors stop aligning, or the slab begins to shift.

Table of Contents

ToggleThis in-depth guide is written for Edmonton homeowners, builders, and property investors who want clear, practical answers. Drawing on real-world experience from professional concrete work in the Edmonton area, we’ll explain what garage pads are, how they differ from slabs, why local climate matters, and what options work best in Alberta conditions.

What Is a Garage Pad?

Properly designed garage pads in Edmonton must account for both structural loads and environmental stress caused by frost movement.

A garage pad is a reinforced concrete base designed to support a garage structure and the loads placed on it—vehicles, tools, storage, and sometimes heavy equipment. In Edmonton, garage pads must be engineered to handle both structural loads and environmental stress, particularly frost movement caused by freeze-thaw cycles.

Unlike interior concrete floors, garage pads are directly exposed to moisture, cold temperatures, and soil movement. This makes proper design, reinforcement, and installation far more important than many homeowners expect.

Garage Pad vs Garage Slab

Although the terms are often used interchangeably, there are practical differences between a garage pad and a standard concrete slab:

- Garage pad: Typically designed specifically for detached or accessory garages, often floating or frost-protected.

- Garage slab: May be tied into a full foundation system, especially for attached garages.

In Edmonton, most detached garages are built on floating garage pads. These pads “float” on compacted gravel rather than being tied to frost walls, allowing controlled movement without structural damage.

Why Garage Pads in Edmonton Require Special Design

Edmonton experiences more than 100 freeze-thaw cycles per year, according to Environment and Climate Change Canada. When moisture in the soil freezes, it expands, causing frost heave. When it thaws, the soil settles unevenly. Without proper preparation, a garage pad can crack, tilt, or sink within a few seasons.

Most failures seen in garage pads in Edmonton are the result of poor base preparation and inadequate frost protection.

A well-built garage pad accounts for:

- Local frost depth (often 8 feet or more)

- Clay-heavy soil common in Edmonton

- Drainage and surface water control

- Vehicle load requirements

Skipping these considerations may save money upfront, but it almost always leads to costly repairs later.

Types of Garage Pads in Edmonton

Not all garage pads are built the same. The right type depends on garage size, usage, soil conditions, and budget. Below are the most common garage pad systems used in Edmonton.

Floating Garage Pads

Floating garage pads are the most popular choice for detached garages in Edmonton. Instead of extending footings below frost depth, these pads rest on a thick, well-compacted gravel base that allows the slab to move slightly without cracking.

Floating garage pads in Edmonton perform well when installed with sufficient gravel depth and mechanical compaction.

Best suited for:

- Detached garages

- Standard vehicle storage

- Residential properties

Advantages:

- Lower cost compared to full foundations

- Faster installation

- Performs well when properly engineered

Limitations: Floating pads must be installed correctly. Poor base compaction or inadequate thickness is one of the most common causes of garage pad failure in Edmonton.

Frost-Protected Garage Pads

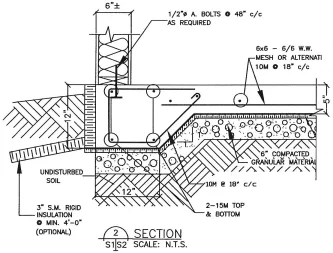

Frost-protected garage pads use rigid insulation around the slab perimeter to reduce frost penetration beneath the concrete. This system is recognized by Alberta building codes and is often required for heated garages.

According to the National Building Code of Canada, frost-protected shallow foundations can be used when insulation values and placement meet specific requirements. This method reduces excavation depth while still protecting against frost heave.

Common applications:

- Heated garages

- Larger custom garages

- Garages attached to living space

Reinforced Concrete Garage Pads

Reinforcement is not optional in Edmonton—it’s essential. Reinforced garage pads use either steel rebar, wire mesh, or both to control cracking and improve load distribution. Reinforcement plays a critical role in ensuring garage pads in Edmonton resist cracking and long-term settlement.

For most residential garages, professionals recommend:

- Concrete thickness of 4–6 inches

- Rebar grid or heavy-gauge wire mesh

- Thickened edges for added strength

Garage Pads in Edmonton: Installation Process Explained

Professional garage pad installation follows a precise process. Each step builds on the last, and skipping any one of them can compromise the entire structure.

Site Preparation & Excavation

The process begins with excavation to remove topsoil and organic material. In Edmonton, this step is critical because clay-rich soil retains moisture and expands when frozen.

A typical excavation includes:

- Removing unsuitable soil

- Establishing correct elevation

- Allowing space for gravel base and concrete thickness

Experienced concrete crews evaluate drainage patterns at this stage, ensuring water flows away from the garage pad—not toward it.

Base Material & Compaction

A strong garage pad depends on what’s underneath it. Crushed gravel is placed in layers and mechanically compacted to create a stable base.

Industry best practices in Edmonton typically require:

- 6–12 inches of crushed gravel

- Layered compaction

- Laser-level grading

According to concrete industry studies, improper base compaction is responsible for more than 70% of slab settlement failures. This step is where professional experience makes a measurable difference.

“Concrete doesn’t fail on its own—most failures start with what’s underneath it.”

— Concrete Construction Magazine

Formwork & Elevation Control

Once the base is compacted, formwork is installed to shape the garage pad and lock in precise elevations. In Edmonton, even small elevation errors can cause long-term problems such as poor drainage, ice buildup at the garage door, or water intrusion.

Professional crews use laser levels to ensure:

- Proper slope away from the garage opening

- Correct finished height for garage door clearance

- Consistent thickness across the entire pad

Forms also define thickened edges, which add strength where walls and vehicle loads are concentrated.

Rebar & Reinforcement Installation

Steel reinforcement is installed after formwork is set. In Edmonton, rebar is preferred over light wire mesh for most garage pads due to its superior crack control and load distribution.

Typical reinforcement standards include:

- Rebar spaced 16–24 inches on center

- Rebar chairs to keep steel centered in the slab

- Extra reinforcement at door openings and edges

This step ensures the garage pad can handle not just passenger vehicles, but also trucks, trailers, and seasonal equipment.

Concrete Pouring & Finishing

Concrete placement must be done efficiently and evenly. In Edmonton, most garage pads use a concrete mix rated between 25–32 MPa, which balances strength and durability in cold climates.

Finishing options include:

- Broom finish: Slip-resistant and ideal for garages

- Steel trowel finish: Smooth, often used for polished interiors

Control joints are cut or formed to guide cracking in a controlled, predictable pattern—an essential detail that protects the slab long-term.

Curing & Initial Protection

Curing is one of the most misunderstood steps in concrete work. Concrete gains strength over time, not instantly. In Edmonton’s dry summers and cold shoulder seasons, improper curing can weaken the surface.

Best practices include:

- Moist curing or curing compounds

- Protection from early freezing

- Limiting foot traffic for 24–48 hours

Most professionals recommend waiting at least 7 days before parking vehicles on a new garage pad.

How Much Does a Garage Pad Cost in Edmonton?

The cost of garage pads in Edmonton reflects the level of preparation, eeinforcement, and compliance with local building codes. Understanding what goes into pricing helps homeowners budget realistically and avoid surprises.

Average Garage Pad Cost in Edmonton

As of recent market data, typical garage pad pricing in Edmonton ranges between:

| Garage Size | Estimated Cost Range |

|---|---|

| Single Car | $4,000 – $6,500 |

| Double Car | $6,500 – $10,000+ |

These figures reflect professional installation using proper base preparation and reinforcement—not budget shortcuts.

Factors That Affect Garage Pad Pricing

- Garage size and thickness

- Amount of excavation required

- Rebar vs wire mesh

- Accessibility of the site

- Seasonal scheduling (spring and summer are busiest)

DIY vs Professional Installation

While DIY garage pads may appear cheaper, they often lack proper base compaction, reinforcement placement, and finishing. According to concrete industry surveys, repair or replacement costs within five years are significantly higher for DIY slabs.

Hiring experienced Edmonton concrete professionals reduces risk and ensures compliance with local codes.

Edmonton Building Codes & Permits for Garage Pads

When a Permit Is Required

In Edmonton, most detached garages require permits. This includes review of foundation type, setbacks, and structural design.

Frost Depth & Alberta Code Requirements

Alberta building codes address frost protection through either deep footings or approved frost-protected shallow foundations. Working with local contractors ensures your garage pad meets inspection requirements.

Garage Pad Maintenance & Longevity

How Long Does a Concrete Garage Pad Last?

With proper installation and maintenance, a concrete garage pad in Edmonton can last 30–40 years or more.

Seasonal Maintenance Tips

- Seal the concrete every 3–5 years

- Remove snow promptly to reduce moisture absorption

- Inspect joints and edges each spring

Preventing Cracks & Surface Damage

Hairline cracks are normal, but large structural cracks are not. Early sealing and drainage management greatly reduce long-term damage.

Common Garage Pad Problems & How to Avoid Them

Cracking & Settlement

Most cracking issues stem from poor base preparation or inadequate reinforcement. These problems are preventable with proper installation.

Frost Heave & Drainage Issues

Ensuring proper slope and insulation prevents frost-related movement—one of the most common issues seen in Edmonton garage pads.

Frequently Asked Questions About Edmonton Garage Pads

How thick should a garage pad be in Edmonton?

Most residential garage pads are 4–6 inches thick with thickened edges.

Can garage pads be poured in winter?

Yes, but it requires heated enclosures and cold-weather concrete practices.

Do garage pads need rebar?

Yes. Rebar significantly improves durability and crack control.

Why Choose a Professional Concrete Contractor in Edmonton?

Local expertise matters. Edmonton soil, climate, and codes require experience—not guesswork. Professional crews bring modern equipment, tested processes, and warranties that protect your investment.

“Concrete is permanent—mistakes are too.”

— Canadian Concrete Construction Association

Get a Free Garage Pad Quote in Edmonton

If you’re planning a new garage or replacing an existing pad, working with an experienced Edmonton concrete contractor ensures long-term performance and peace of mind.

Our team provides:

- Garage pads

- Concrete flatwork

- Driveways

- Cribbing and foundations

If you are planning garage pads in Edmonton, working with experienced local concrete professionals ensures durability and long-term value, contact us today to request a free, no-obligation quote and get expert guidance tailored to your property and budget.